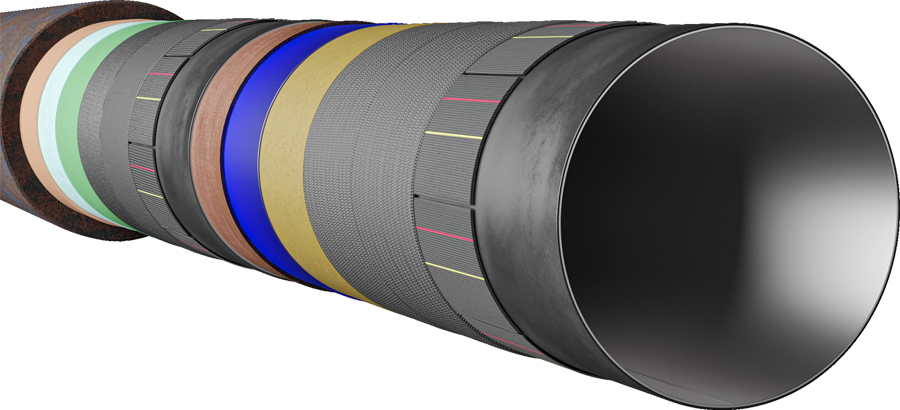

The photo above shows multiple 18” diameter x 300 ft. ITC vertical storage vessel prototypes produced by our Portable Manufacturing Platform (PMP) and being readied for bore insertion field testing. The model on the right demonstrates our ITC vessel layers with steel compression coupler installed.

Parallel to the SG Liner, we're making revolutionary strides with the ITC horizontal, vertical, and coiled energy storage solutions. These linear ITC composite vessel systems offer high volume, versatile storage solutions for Hydrogen and other gases. The ITC’s novel design increases storage volumes while conversely minimizing potential failure points by an order of magnitude as compared to H2 tube trailers, vessel racks and vessel container systems. This makes the ITC safer and more space-efficient, while affording nearly 82,000 kg of hydrogen storage per acre-per level at a per kilogram capital cost reduction of over 25% compared to contemporary hydrogen storage systems. To locally store 82,000 kg of Hydrogen would require around one hundred seventeen (117) hydrogen tube trailers / vessel containers / vessel racks and 7 acres of laydown area as compared to 1 acre with the ITC vessel system.

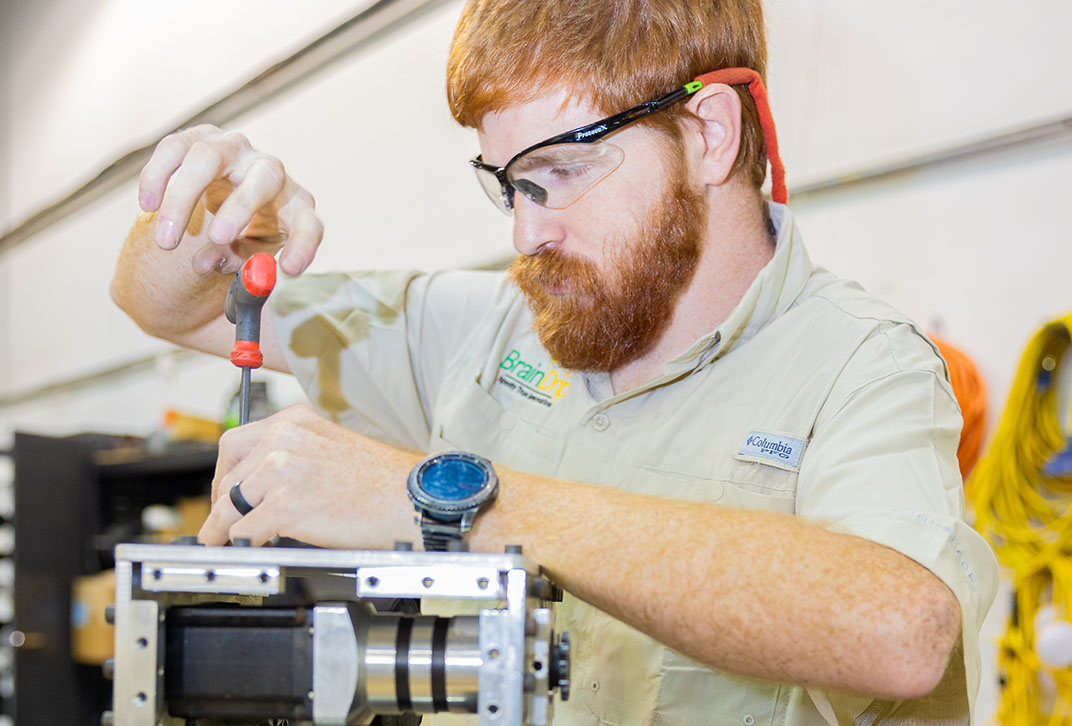

Manufacturing of the ITC Vessel Systems is made possible through our Portable Manufacturing Platform (PMP) or our Autonomous Manufacturing Vehicle or AMV, which are equipped with cutting-edge autonomous navigation, auto attuned manufacturing and AI, CV, and ML - QA/QC systems, ensuring precision and integrity at every step. The ITC storage systems designs allow them to be easily incorporated into various settings, platforms, configurations, and subterranean options offering enhanced safety, increased capacity, and environmental benefits.

Recent News: In 2023, we completed a contract with the submittal of an 86-page feasibility study through IQ4H2, for the utilization of the ITC storage systems for localized renewable energy storage. The results were, and to quote our client, “incredibly exciting”. Our governmental client is currently evaluating commencement dates for full FEED study and onsite pilot project.